In today’s rapidly evolving technological landscape, one innovation that is revolutionizing the manufacturing industry is lsr silicone molding. This cutting-edge technology has transformed the way products are designed and produced, offering numerous advantages over traditional manufacturing methods.

The Advantages of LSR Silicone Molding

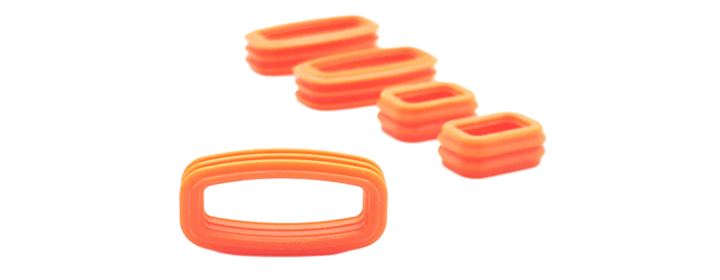

LSR silicone molding utilizes liquid silicone rubber (LSR) to create highly precise and complex parts with exceptional quality. The process involves injecting liquid silicone into a mold cavity, which then cures at room temperature or under heat to form the desired shape. This method offers several key benefits:

- Precision: LSR silicone molding allows for intricate designs and tight tolerances, ensuring consistent and accurate production of even the most complex components.

- Durability: Products manufactured using LSR silicone molding exhibit excellent durability, withstanding extreme temperatures, chemicals, UV exposure, and other harsh conditions without compromising performance.

- Elasticity: The inherent flexibility of LSR enables it to stretch without losing its original shape or properties. This makes it ideal for applications requiring elasticity or resilience.

- Biocompatibility: LSR materials are biocompatible and hypoallergenic, making them suitable for medical devices such as implants or prosthetics.

- Cost-effectiveness: Despite its advanced capabilities, LSR silicone molding can be a cost-effective solution due to reduced labor costs and shorter production cycles compared to traditional manufacturing techniques.

JVTECH: Pioneering Innovation in LSR Silicone Molding

A leading player in the field of LSR silicone molding is JVTECH, a renowned manufacturer specializing in the production of high-quality silicone products. With state-of-the-art facilities and a team of experienced engineers, JVTECH leverages LSR technology to deliver innovative solutions across various industries.

By harnessing the advantages of LSR silicone molding, JVTECH offers customized manufacturing services that meet the unique requirements of their clients. From automotive components to consumer electronics and healthcare devices, their expertise spans a wide range of applications.

LSR Brand Consulting: Maximizing Potential with LSR Silicone Molding

To fully leverage the potential of LSR silicone molding, companies often turn to experts like lsr brand consulting. This consultancy firm specializes in helping businesses optimize their product development processes using this advanced manufacturing technique.

LSR Brand Consulting provides comprehensive guidance on material selection, design optimization, tooling development, and process validation for successful implementation of LSR silicone molding. Their expertise ensures that companies can achieve superior product quality while minimizing costs and time-to-market.

In Conclusion

The advent of LSR silicone molding has revolutionized manufacturing by offering unparalleled precision, durability, elasticity, biocompatibility, and cost-effectiveness. Companies like JVTECH are at the forefront of this technological advancement while consulting firms such as LSR Brand Consulting provide invaluable support in maximizing its potential. As we continue to embrace innovation in manufacturing processes, it is evident that LSR silicone molding will play an increasingly vital role in shaping our future.